Intralogistics, automation, handling

High cost efficiency with reliable 24/7 quality is required in the field of automation, robotics and intralogistics. When it comes to exact positioning tasks, electric grippers, handling devices and weighing and conveying systems, ZAE gear units perform first-class work thanks to their high power and torque density and longevity.

High cost efficiency and premium quality

Digitalisation of the industry has direct implications for performing automation, robotics and intralogistics processes. New technical advances in these areas facilitate innovations that change markets. At the same time, high cost efficiency and quality are in demand, which is a challenge, for example, for automated systems that operate 24/7.

ZAE gear units are built to meet these requirements. Depending on the application specification, they play out their specific strengths, e.g. high dynamics, power density, high short-term overload capacity, compact, robust design or precision.

Strong standard gear units

We know that pick-and-place applications require high rigidity, repeat accuracy, precision and high permissible acceleration torques, while dynamic, linear handling applications require particularly robust, high-duty/long living components. Multi-axis systems sometimes require mathematically accurate ratios. In stationary intralogistics, on the other hand, high levels of efficiency, quiet, smooth running and durability are crucial.

Common to all applications is the need for an extremely long service life and reliability.

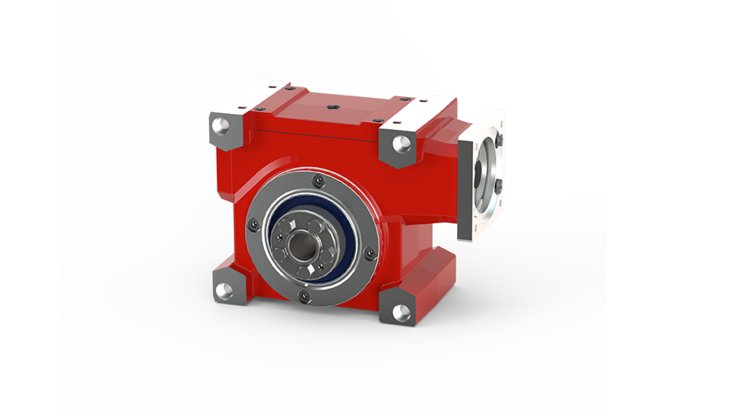

And that is an absolute strength of our standard gear unit and the new ZAE SERVO DRIVE.

Are you already familiar with the ZAE Servo Drive? Our new development is ground-breaking in many ways.

You can find out more about it here.