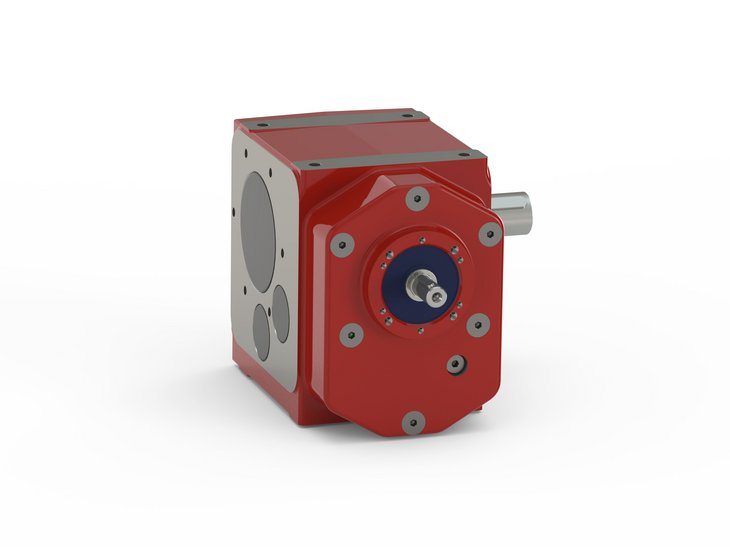

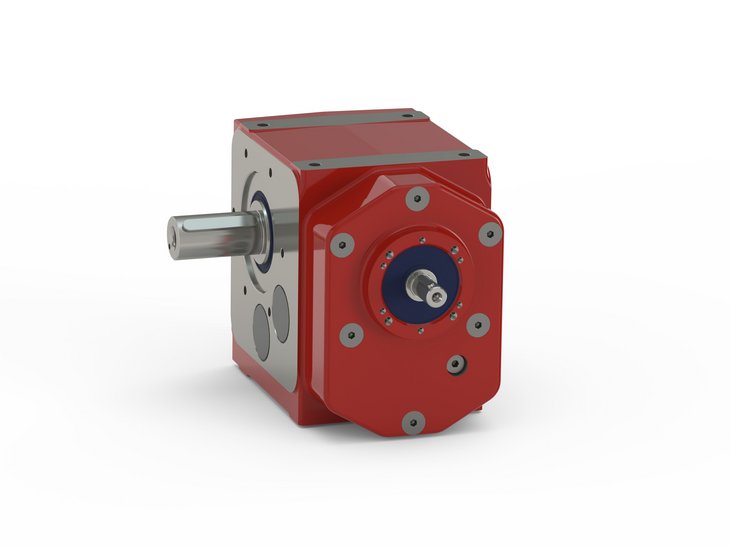

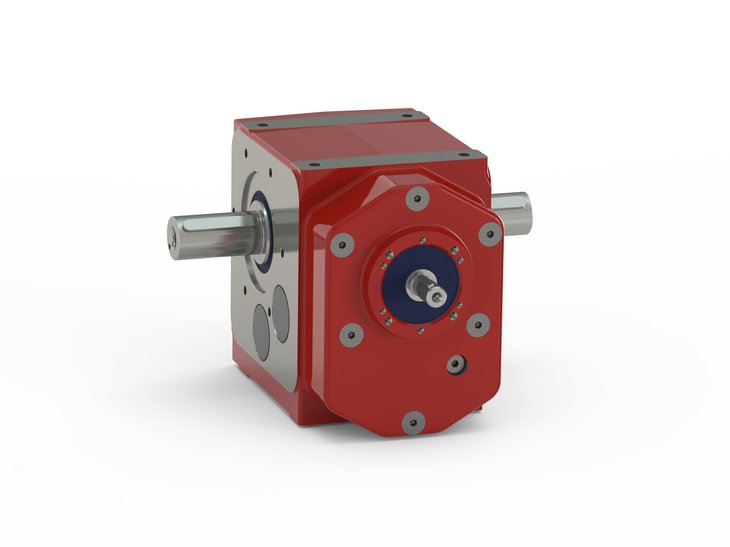

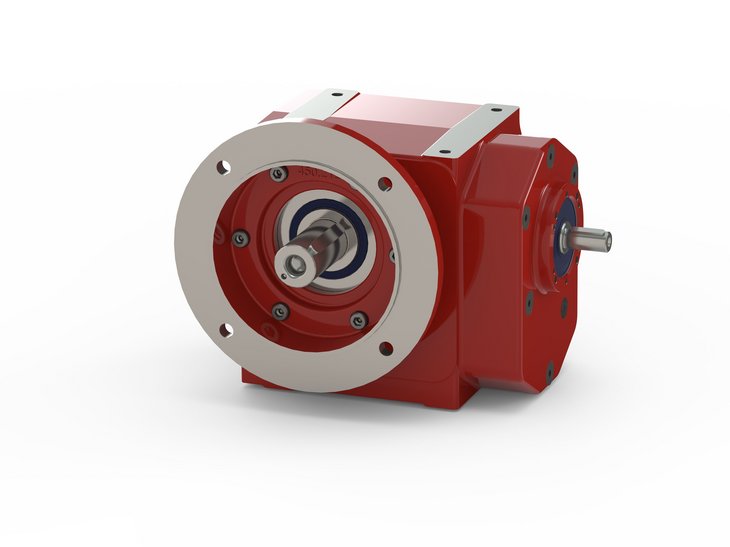

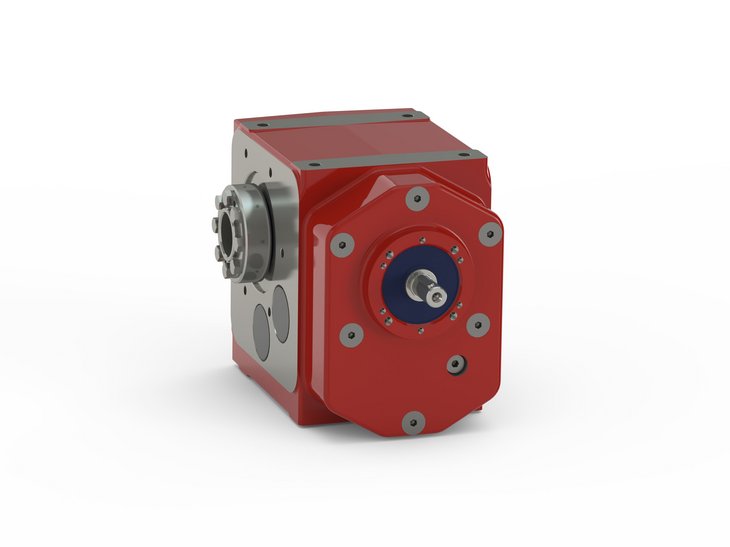

Helical worm gear units

These gear units combine the advantages of worm gear units with those of spur gear units:

In the high-speed range of the first gear stage, under lubrication-favourable conditions, the multi-speed worm shaft operates with an efficiency of up to 95%.

This is where the worm gear stage demonstrates its excellent vibration damping properties for optimised smooth running. Precise spur gear sets run in the second or third gear stage downstream with likewise excellent efficiency at low speed.

Benefits

- Vibration and shock-absorbing

- Quiet, damping operation

- High power density

- Output side with hollow shaft, one-sided or double-sided shaft

- 2 or 3 gear stages in the same housing

- Excellent efficiency

- Maintenance-free

- IEC motor attachment, servo motor attachment or free shaft end

- Various modifications available

- Clamping set option on the hollow shaft